Pivot International and Our Global Family of Companies: A Comprehensive Overview

Pivot International started in 1972 as a contract manufacturer with a small engineering team. Now in business for over 50 years, we’ve grown to become a global product development, engineering, and manufacturing company. We’ve strategically increased our capabilities and global footprint to better serve our partners. We don’t just engineer to make something—we engineer to manufacture. Over the past several years, we have made strategic acquisitions to increase our skills, bringing in experts with a wide range of capabilities.

While still offering contract manufacturing, our teams now work with our partners at every stage of the product development process, from design to manufacturing. Our contract manufacturing services give our partners access to our global supply chain teams, design for manufacturing feedback, and manufacturing facilities throughout three continents.

Pivot has successfully developed products for a wide range of markets, including medical, industrial, sports and entertainment, agriculture, security and defense, and construction.

Growing Our Capabilities

- 1985: Expanded into Asia by opening an engineering office in Taiwan

- 1989: Established our first manufacturing facility in the Philippines

- 2013: Opened supply chain and sales operations in Shenzhen

- 2014: Established business development office in Europe

- 2015: Opened second manufacturing facility in the Philippines

- 2016:

- Opened business development and sales operations in Hong Kong

- Acquired MCC Electronics, a custom electronic design and manufacturing company in the Kansas City area

- Acquired DigitTron Technologies, Inc., which develops electronic components in the KC metro

- 2017:

- Acquired Avatar Engineering, Inc., in Lenexa, Kansas

- Acquired Electronic Design and Manufacturing, in the Omaha, Nebraska area

- 2018: Acquired Wideblue in Glasgow, Scotland

- 2019:

- Acquired A2E Limited in Livingston, Scotland

- Acquired Castle Creations, which develops motors for hobby and commercial markets, in the Kansas City area

- 2020: Acquired Digital Concepts of Missouri Inc.

Pivot Today

Over the last 50 years, we have grown our footprint in skills and assets and currently have 13 locations worldwide. Pivot has also grown to over 800 employees throughout the world, more than 100 of which are part of our multi-disciplined engineering teams. Additionally, we have over 300,000 square feet of manufacturing space across North America, Europe, and Asia, equipped with the technology and skillset needed to make a product idea a reality.

Our Teams

Our multi-disciplined engineering teams are prepared to work with you to design a product from an idea or work with an existing specification. Our teams include electrical engineers, mechanical engineers, and software engineers with experience developing products together and designing for manufacturing. Our prototyping services will aid in testing the design and capability of the product and redesigning it until it’s ready for production at one of our global facilities.

Our mechanical engineers have experience designing products for a wide range of markets. All products are developed with manufacturing, durability, and regulatory compliance in mind. Whether designing a product from initial concept or working with an existing design, our team is well versed in making your product a commercial success.

As a full-service product design and development company, we are experts in industrial design. Our team’s vast experience designing for industrial applications means they understand how to work with partners to achieve the optimum look and functionality of a product.

Each project we work on is assigned a project manager. Our managers work closely with our partners to ensure they are informed and satisfied every step of the way. Our project managers establish goals, track progress, and use resources effectively and within budget.

Working with Pivot means working with award-winning electronics designers. We have received multiple European Product Design Awards, a German Design Award, and were recognized as a Gold Winner by the Medical Design Excellence Awards.

We Design for Manufacturing

At Pivot, we integrate design for manufacturing (DFM) practices at all stages of the product development process. Our engineering teams design all products in alignment with DFM principles. DFM allows for a more optimized, cost-effective design that is easily scalable and can be sold across global markets.

Pivot International has 300,000 square feet of manufacturing space and 17 fully automated SMT lines. We also have an advanced change order system, which allows for rapid product updates without inventory gaps.

Our partners have the power to choose where their product is manufactured. Products manufactured in the US cost more in workers’ wages but save on shipping and import taxes associated with internationally manufactured products.

Regulatory Compliance

Our facilities are FDA-registered, ISO 9001:2015 and ISO 13485:2016-certified, and conform to IPC standards. We have quality management systems at site level that control the selection, evaluation, and monitoring of suppliers. We also align with global quality standards and can integrate with our partners’ quality management systems as needed.

In addition to certifying our systems, we are also experienced in getting products approved by regulatory agencies. Our manufacturing facilities produce UL-listed, CSA-approved, and TÜV SÜD America-certified devices.

A Global Network of Product Development

Pivot International’s global teams offer a one-stop shop for product development. Our partners can pull from our worldwide resources—mechanical engineers in Kansas can work with optical designers in Scotland, who work with electronic engineers in Taiwan.

Supply Chain Team

Our global supply chain team works with project managers to order parts, which are shipped to one of our manufacturing facilities in the US, Philippines, China, or Mexico. Our team is experienced in working across multiple markets and is dedicated to acquiring reliable, cost-effective parts. Our supply chain teams are also experts at navigating import and export processes to efficiently deliver the parts for your product. We use an early warning alert system to identify potential disruptions before they affect manufacturing.

Pivot International’s Family of Companies:

Pivot International

Our global headquarters, located in Lenexa, Kansas, has engineering, design, and product management resources. Pivot International also provides the foundation for business development, global supply chain, and quality management. Pivot is also located near Avatar Engineering, DigitTron Technologies, MCC Electronics, and Castle Creations manufacturing facilities.

Pivot UK

Pivot UK is our European headquarters for supply chain and business development. It supports our two UK-based companies, Wideblue and A2E.

Pivot Taiwan

Pivot Taiwan is our Asian headquarters for engineering and design. This office is also a supply chain and quality management hub, supporting our operations in Asia and our global organization.

Pivot Shenzhen

Pivot Shenzhen is our Asian headquarters for quality management and supply chain in the global market. They are also experts in sales operation functionality.

Pivot Hong Kong

Pivot Hong Kong manages business development and sales operations. It acts as a hub for communications across our Asian markets.

Pivot-Hawks Manila

Our 78,500 square foot manufacturing space in Manila, Philippines, has over 250 employees. Specializing in medium- and large-volume PCB manufacturing and box builds, Pivot-Hawks has two fully automated SMT lines that are mirrored with one of our US-based facilities, EDM. Capabilities include ultrasonic welding, full functional testing, and full product traceability. The facility has Class 7 and Class 8 cleanrooms, and DFM is integrated into all manufacturing processes. This FDA-registered facility offers an integrated and secure gated design process.

Avatar Engineering

Avatar Engineering is located in Shawnee, Kansas, which is a short 20 minute drive from our global headquarters. This short- to large-volume PCB manufacturing facility offers fully automated SMT and through-hole electronic assembly, box builds, full functional testing, automated potting capabilities, and automated conformal coating. Avatar applies DFM practices, fabrication and test techniques, and conforms to industry standards. It also offers IPC-certified design engineers, assembly technicians, and a full test and rework department.

Castle Creations

Established in 1997 and acquired by Pivot International in 2019, Castle Creations specializes in low-weight, high-power, brushless DC motor and controller solutions. Castle Creations is a leader in brushed and brushless motor design, with experience in direct belt and geared drive trains. Castle has delivered over 1 million brushless DC motors for consumer and industrial applications. Its motors are designed for thermal performance, ensuring consistent output throughout operation and long motor life. Its medium- to large-run PCB manufacturing and product assembly facility has two fully automated SMT lines, automated optical inspection, automated potting, test and rework, conformal coating (dip or spray), overmolding, heavy gage wire soldering, and dynamometer testing.

Digital Concepts (DCI)

DCI is our experts in operator interface systems. Established in 1990 in St. Louis, DCI works closely with customers to develop custom interfaces for their products. DCI has experience with a wide variety of user interface formats, including large- and small-format LCDs, custom keypads and displays, touchscreens, custom device lighting and indicators, audio indicators and alerts, and integrated global TV tuners.

-

DCI China

DCI has a manufacturing facility in Suzhou, China. The 60,000-square-foot facility offers three fully automated SMT lines, PCBA and console assembly, BGA technology, conformal coating, finished goods assembly, prototype builds, cross-trained operators quality system-document control, and fine pitch, axial, and manual part placement.

-

DCI Mexico

DCI’s Mexico facility in Juarez handles medium- to large-volume PCB manufacturing. The facility’s three fully automated SMT lines mirror DCI’s China facility. The facility offers customized small builds, BGA technology, finished goods assembly, conformal coating, prototype builds, quality systems, cross-trained operators, and fine pitch, axial, and manual part placement.

DigitTron Technologies

DigitTron is our US-based small- to large-run design and manufacturing facility. Specializing in surface-mount electric manufacturing, DigitTron offers fully automated SMT and through-hole electronic assembly. This Kansas City area facility manufactures up to 12-layer PCBAs and offers automated potting, conformal coating, and full functional testing. DigitTron’s X-ray machine is a testament to their commitment to quality control.

Electronic Design and Manufacturing (EDM)

EDM offers 51,000 square feet of manufacturing space in the Midwest. It features three mirrored SMT lines with Pivot-Hawks. If a natural disaster happens at either facility, design files can be seamlessly transferred to the other location to avoid additional delays. EDM has full functional testing and rework, automated potting and conformal coating, wave and selective solder, laser marking, over-molding capabilities, and a Class 8 cleanroom. The FDA-registered facility also has IPC-certified design engineers and assembly technicians, automatic optical inspection, and BGA removal, replacement, and reballing.

MCC Electronics

MCC Electronics (MCCE) is our design and manufacturing facility specializing in electric hydraulics for industrial markets. MCCE offers prototype to medium-volume product assembly and industrial controls manufacturing. The facility manufactures IP67-approved devices and integrates DFM practices throughout all manufacturing processes. MCCE also has potting and conformal coating, through-hole PCBA and assembly, full functional testing, and box build capabilities.

Pivot A2E

Pivot A2E is our experts in sensor technology for the oil and gas and underwater industries. A2E develops products for harsh, potentially explosive environments and has over 20 years of experience in sensor development and electronics design solutions. They also have experience developing ATEX and IECEx certified products, and are well-versed in subsea applications. A2E has also developed products for the renewable energy market and has contributed to a wide variety of medical device developments.

Wideblue

Wideblue was established in 2001 as a division of Polaroid’s European Design Center and became an independent company in 2006. Wideblue are experts in optical design, specializing in photonics, imaging, and optical systems for consumer, industrial, and medical markets. Illumination and imaging systems are tested in Wideblue’s optical lab. They design and develop for a wide range of optical emission and detection systems. They also have expertise in quantum theory and technology, developing several products in the space sector.

Full-Service Product Design and Development

Pivot International is an experienced design and manufacturing company that works with our partners to develop designs for their products, update or revise existing designs, and provide manufacturing services at our global facilities. Our multi-disciplined engineering teams and global supply chain network are experts in design for manufacturing and sourcing. With Pivot, you get comprehensive end-to-end visibility, so you know what is happening at every step of the process. Our quality management systems and alignment with manufacturing certifications and standards ensure that we deliver a market-ready product. No matter the market, our team is here to help. Contact us today to learn how Pivot International’s family of companies can work for you.

Pivot’s Aggressive Growth Strategy Skyrockets it to the Top 1% of Fastest-Growing Businesses

Our team at Pivot International is proud to announce that Pivot has been named a winner of Ingram’s 35th Annual Corporate Report 100 competition, which ranks Kansas City’s 100 fastest-growing businesses. Pivot’s 11th place ranking represents its status as among the top 1% of the area’s 75,000-plus businesses.

Since 2016, Pivot has achieved an annual growth rate of 141%, expanding its talent pool from 136 to nearly 700. In the last four years alone, our team’s aggressive yet calibrated growth strategy has resulted in the acquisition of eight new subsidiaries. This accelerated growth enables us to deliver our elite product design, engineering, development, manufacturing, and distribution expertise across fourteen industries.

Pivot’s portfolio of companies includes:

- MCC Electronics Inc., a US-based design and manufacturing facility that specializes in electric hydraulics for heavy industrial markets.

- DigiTron Technologies Inc., a US-based small- to large-run design and manufacturing facility that specializes in surface-mount electric manufacturing.

- Avatar, our US-based engineering experts that specialize in motor control and IoT solutions, with manufacturing capacity for short and medium inventory runs of electronic product solutions.

- Pivot A2E Scotland, our UK-based engineering experts that specialize in sensor development and electronics design solutions for implementation in potentially explosive conditions.

- EDM Electronics Design & Manufacturing, a US-based large-scale production facility with high capacity PCBA and box build capabilities.

- Wideblue, a Scotland-based award-winning design firm with expertise in imaging and optical engineering.

- Castle Creations, US-based experts in low-weight, high-power, brushless DC motors, and controller solutions.

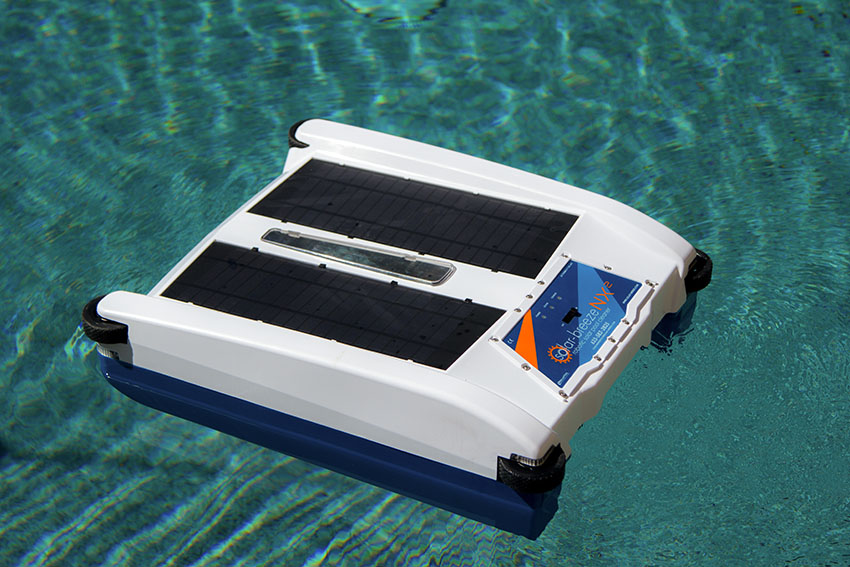

- Solar-Pool, US-based experts in patented solar-powered technology with strengths in robotics, harsh environments, and floatation devices.

By leveraging a highly agile one-source model and advanced supply chain technologies, including the latest in SMT digital twinning, Pivot is leading the industry with alternative sourcing solutions for businesses impacted by COVID-19 disruption, ongoing US-China trade tensions, and the growing skills-gap crisis.

With offices across the US, London, Glasgow, Edinburgh, Taiwan, Manila, and Hong Kong, Pivot’s global presence makes it a go-to resource for companies worldwide. Pivot brings IEC (60601-1) and ISO certification (9001:2015, 13485:2016, and ISO 80079-34), FDA registration, UL listing, and CSA approval. And with company-owned operations and 200,000 square feet of manufacturing capability across three continents for serving US, Asia, and European markets, Pivot is fast becoming the preferred partner for defying disruption, seizing emerging opportunities, and successfully scaling for a new era.

Contact us today to see the difference a high-growth company with nearly a half-century of proven experience can make to your company’s success.

Pivot International Acquires Solar Pool Technologies

Pivot continues to expand its consumer-products portfolio and enhance its consumer-market position with the acquisition of Phoenix Arizona-based Solar Pool Technologies, a leader in solar-powered robotic swimming pool skimmers.

Solar Pool Technologies, maker of the robotic pool skimmer, Solar Breeze, was founded in 2011. Leveraging patented technology in the solar-powered robotic pool accessories space, its market presence spans 44 states and 17 countries.

Pivot has engineered and manufactured products for Solar Breeze since 2017. “Joining Pivot International will enable us to grow more rapidly with our industry-leading technology,” explained Solar Pool Technology founder and President Paul Sim. “[Pivot] has the resources, engineering capabilities, and global manufacturing capacity to design, manufacture, and distribute products all over the world. I’m excited about our future together,” concluded Sim.

Pivot International has enjoyed explosive growth in recent years with its ONE-SOURCE business model for the development, design, engineering, and manufacturing of products for clients all over the world in various industries. Combined with its capabilities, talents, and assets: Pivot International’s business philosophy helps fuel growth for its customers.

A Letter from our CEO

As we all navigate the treacherous COVID-19 outbreak and determine the impact on our families, businesses, staff, communities, and the world, there are many short- and long-term implications that need to be addressed. Pivot has the manufacturing-capability to solve your supply chain challenges, close your inventory gaps, and meet your immediate product needs. We can also be your strategic partner to help you improve on opportunities that emerge in relation to the current crisis.

Pivot International is uniquely positioned to offer solutions. Whether your company is large or small, we leverage advanced design and engineering expertise to serve your medical- and security-product needs. Our agility enables us to quickly respond to challenges and we have rapidly repurposed and ramped up our manufacturing operations in the US, Europe, and Asia. We are a qualified Critical and Essential Supplier with nearly 50 years of experience in more than 12 industries, including medical. We are ISO 9001 and 13485 certified, FDA-registered, and have four U.S.-based manufacturing facilities (totaling roughly 100,000 square feet), as well as two Philippines-based manufacturing facilities (totaling roughly another 100,000 square feet, equaling approximately 200,000 square feet worldwide).

Contact me. We can help solve your short- and longer-term challenges.

Mark Dohnalek

CEO and President

[email protected]

913-312-6900

Pivot International Acquires Castle Creations

We’re thrilled to announce that Castle Creations, the leading aftermarket manufacturer of high-performance electronic speed controls and brushless direct current (DC) motors for radio-controlled (R/C) car, air and multirotor hobby applications and industrial unmanned aerial vehicles, is now part of the Pivot International family!

Acquiring the Kansas City-based Castle Creations has given us the opportunity to enter the electronics speed control and brushless DC motor retail markets.

Castle Creations holds 16 patents and has 22 years of innovation in brushless DC motor design and motor control algorithms, with a reputation for superior performance, configurability and quality. Beyond simply being an aftermarket parts provider for other brands, Castle Creations has become a widely-recognized and well-respected name in the industry. Additionally, the company’s strong reputation for creating high-quality, versatile products and providing unparalleled “make-it-right” customer support have earned it an ever-growing base of loyal customers.

Castle Creations’ leadership in the R/C hobby market has also created new opportunities for the company in commercial applications, including firefighting, helicopter aviation, cooling systems, fuel pumps, underwater propulsion systems, and more.

Combining Pivot International’s global presence with Castle Creations’ technical expertise is a win-win for us both. This will enable us to further expand our technical footprint, while also giving us a great product range to offer our clients.

We’re proud to have such a strong consumer brand, with broad distribution through hobby distributors, local hobby shops, Amazon and direct-to-consumer, as a part of the Pivot International family.

The acquisition of Castle Creations marks Pivot International’s seventh acquired company in over three and a half years, and our fourth acquired company in the last two years. It’s also our biggest acquisition yet.

This acquisition also continues Pivot International’s growth strategy of taking an aggressively calibrated approach to organic and acquired competencies, capacity, expertise and assets to help our customers meet their market and global clients’ needs most effectively. Additionally, this bold approach has served as the backbone for the massive growth we’ve experienced in the past few years.

Over the last five years, Pivot International has had an annual growth rate of 141%, and we have increased our number of staff members from 136 to nearly 700. On top of this, we also have facilities in 11 locations around the world.

Additionally, our approach ensures that we’re able to respond to any changes and new developments in the industry, like the imposition of China taxes and tariffs, with speed and agility by providing alternative options and solutions for our clients. We’ve also invested in surface mount technology in the U.S. and Asia, so that we can simultaneously manufacture products on two continents to optimize output and respond to challenges or opportunities.

With offices across the U.S., London, Glasgow, Edinburgh, Taiwan, Manila and Hong Kong, Pivot International is continuing to build a portfolio of talent and resources around the world, creating company-owned manufacturing operations that seamlessly support a global supply chain.

In the words of Pivot International President and CEO Mark Dohnalek, “I am committed to ensuring that Pivot has the global capabilities to design and manufacture in the U.S., the U.K. and Asia, so that we can deliver the most efficient solution for our clients all over the world.”

Pivot Announces Acquisition of A2E Limited

At Pivot, we are always looking for new ways to expand our global capabilities, from electronics hardware and software design services to manufacturing and developing new products.

We are pleased to announce our recent acquisition of A2E Limited, an award-winning design and engineering solutions firm in the oil and gas, defense and security, smart energy, medical, and life science industries.

Based in Livingston in Edinburgh, Scotland, A2E Limited specializes in single-source solutions. The 17-year-old company has extensive development capabilities for hardware and software, and is an expert in concept development and design, prototype testing, and design for manufacturing (DFM).

David Ross, Managing Director of A2E Limited, remarks that the acquisition “will help serve our clients with expanded team of experts, capabilities, resources and locations globally. We are very optimistic about our affiliation with Pivot and its effect for our clients and our employees.”

With A2E Limited, Pivot covers an impressive global roster of over 100 product design engineers, and an overall global organization of over 650 associates. With facilities throughout the US, UK, and Asia, Pivot’s company-owned global resources are uniquely able to produce a wide range of products with the world’s most efficient and effective manufacturing processes.

As noted in a press release, Mark Dohnalek, President and CEO, describes the acquisition as a “calibrated approach to organic and acquired competencies and capacity, expertise and assets” that ultimately “help customers meet market needs and global clients needs most effectively.”

Mark Dohnalek also told the press, “Over the last five years, we have an annual growth of 141%, increased our staff from 136 to 650, and have facilities in 10 locations around the world. This approach ensures that we are able to respond to the needs and changes such as the imposition of China taxes and tariffs with speed and agility by providing alternative options and solutions for our clients. We have also invested in SMT mirrored technology in the US and Asia so that we can simultaneously manufacture products in two continents to optimize output and respond to challenges or opportunities.”

The President and CEO affirms that he is “committed to ensuring that Pivot has the global capabilities to design and manufacture in the US, UK and Asia so that we can deliver the most efficient solution for our clients all over the world.”

For 47-years, Pivot has served as the single-source expert for clients in a broad range of industries, including biometric/security products, wearable technology, touchscreen technology, medical, wireless, fitness, electronic components, agriculture, building operations and consumer products. If you’d like to learn more about how Pivot can help you design, prototype, or manufacture your product, schedule a free consultation with us today.

Wideblue Wows at Med-Tech Innovation Expo

Product design, development and manufacturing consultancy Wideblue wowed attendees at Med-Tech Innovation Expo with its cutting-edge medical products and the ground-breaking technologies behind them.

A leader in medical device design and development since 2006, Wideblue is partnering with the world’s leading medical device companies to deliver pioneering healthcare products to better people’s lives.

Pivot Continues Its Industry Ascent with Strategic Investment In SMT

Surface Mount Technology (SMT) is the newest, most effective and efficient electronic manufacturing solution. Utilized in virtually all commercial, industrial and consumer products with electronic features ranging from phones to computers, tablets, coffee makers, automobiles, ioT, biometric and medical products, SMT has broad application and ensures highly accurate execution of high-volume production.

Pivot International, a leading design, engineering, and manufacturing firm has expanded its production capacity with a strategic investment in Surface Mount Technology, providing its customers with the most advanced and cost-savings technology while continuing is rapid ascent to industry dominance.

Mark Dohnalek, President and CEO of Pivot International explains, “This strategic investment expands our global manufacturing capacity and ensures that we are the expert of choice for the highest quality, efficient, consistent production with safeguards to deliver uninterrupted SMT products.” Dohnalek describes the company’s growth strategy as “an aggressive calibrated approach to growth of capacity, expertise and assets in order to help customers meet market needs with Pivot’s global process and resources most effectively.”

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). An electronic device made with this technology is referred to as a surface-mount device (SMD).

Pivot’s investment includes the installation of two mirrored Samsung high-speed SMT lines in its US-based Omaha NE facilities, as well as in its South Asia, Philippines-based Manila facilities. The mirrored lines are identical and can perform simultaneously with twinned specifications to maximize manufacturing volume. Since the mirrored lines share a server and database, Pivot can instantly switch or adjust manufacturing parameters with updates executed on both continents simultaneously.

This mirrored technology is advantageous for customers who distribute globally, allowing them to save time and money by choosing the Pivot facility closest to their products’ shipping destination, and if necessary, flexibly shifting production between Omaha and Manila.

In addition to Pivot’s dual locations serving to optimize customers’ supply chains, Pivot’s multi-continent facilities and mirrored SMT-lines provide yet another layer of protection for customers’ manufacturing production by buffering against natural disasters such as fires or floods, or political or economic upheavals such as strikes, tariff impositions, and currency fluctuations.

In order to support the global markets and serve customers in all geographies around the world, Pivot International continues to build its portfolio of brands, talent and resources with offices in the US, London and Glasgow, UK, Hong Kong and Taiwan. Pivot’s company-owned global resources attract and employ the industry’s top, design, engineering, and production talent to deliver the highest quality and cost-effective services for any product format. With a 47-year track record of integrity, innovation, high performance, and the adoption of leading-edge technology, Pivot has distinguished itself on the global stage as a single-source expert serving clients in a broad range of industries. These industries include: biometric/security products, wearable technology, touchscreen technology, medical, wireless, fitness, electronic components, agriculture, building operations and consumer products. Affirms Dohnalek, “I am committed to ensuring that Pivot has the global capabilities to manufacture in the US, UK and Asia so that we can deliver the most efficient solution for our clients all over the world.”

If you’d like to see how Pivot can be part of the solution to your design, engineering, or production challenge, contact us today for a free, no obligation consultation. We’re here and ready to help.

Pivot Announces Integration of Avatar and DigitTron

PIVOT INTERNATIONAL CO-LOCATES TWO OF ITS GREATER KANSAS CITY AREA SUBSIDIARIES WHILE IT EXPANDS ITS GLOBAL PRESENCE, GROWING FROM A STAFF OF LESS THAN 100 TO 300 EMPLOYEES IN 5 YEARS, 3 TO 10 FACILITIES AROUND THE WORLD, AND COMPOUNDED ANNUAL REVENUE BY OVER 100%.

Subsidiaries DigitTron and Avatar Engineering will integrate office and manufacturing space at the current DigitTron location while maintaining distinctive operations.

DigitTron and Avatar Engineering offices:

23875 West 83rd Terrace

Shawnee, KS 66227

www.digittron.com

www.avatarpivot.com

The move will support the team of exceptional engineers, designers and manufacturing staff to collaborate on leading-edge solutions designed and manufactured on site.

Mark Dohnalek, President and Chief Executive Officer comments “It makes strategic sense, integrates our subsidiaries and optimizes our operations. We’ll leverage our talent, capabilities and capacity while maintaining the distinctive subsidiaries in one shared location. We are able to design and engineer, build prototypes, short-run and full-run production locally.”

Pivot International, with global headquarters in Lenexa, Kansas continues its aggressive organic growth as well as subsidiary acquisition growth to meet client expectations and capacity in design, engineering and manufacturing of electronic solutions across a broad range of industries including industrial, security and biometrics, medical, wireless, fitness, scientific instruments such as electric components, touchscreens, consumer goods, transportation, agricultural, environmental, and internet of things (iOt).

Mark Dohnalek, President and Chief Executive Officer focuses on ensuring that the talent, capabilities and assets across the parent company and 9 subsidiaries work effectively and efficiently to position Pivot International companies as the strongest total solutions partner for Fortune 500 to mid-size to entrepreneurial companies.

Mark Dohnalek, CEO affirms, “I am committed to generating jobs, products and revenue in the US, especially in the Kansas City area and Midwest. I am equally committed to ensuring that Pivot has the global capabilities to manufacture in the US, Europe and Asia so that we can deliver the most efficient solution for our clients all over the globe. While many debate the merits of nationalism versus globalism, I pragmatically understand the need for both in our growth strategy.” Pivot views every opportunity as global while leveraging capabilities from all over the world to bring the product to life.

Pivot International is the parent company of:

MCC Electronics

DigitTron

Avatar Engineering

Electronic Design and Manufacturing (EDM)

Pivot – UK

Pivot – Hawk in Manila

Pivot – Shenzhen

Pivot – Hong Kong

Pivot – Taiwan

Pivot International Acquires WideBlue

Pivot International acquires WideBlue, a full-service, multi-disciplinary product design and development firm based in Glasgow, Scotland. WideBlue specializes in highly technical products that include Optic Technology and other embedded electrical engineering disciplines. It has developed numerous medical products as well as a large array of camera imaging products.

WideBlue was formed as a division of Polaroid’s European Design Center over 20 years ago forming an industry-leading team of experts in imaging technology.

WideBlue is a global award-winning development and engineering firm that provides clients opportunities to design innovative, first-to-market integrated solutions supported with prototype development to manufacturing of short, test runs. Many products in the WideBlue portfolio are the first of their kind, based on novel technology or intellectual property as a result generating several patents. WideBlue’s strength is developing integrated systems that are commercially viable. With Pivot International’s global manufacturing, designing and engineering capabilities, WideBlue will now expand from small runs to full-scale manufacturing production capabilities and capacity.

Mark Dohnalek, CEO of Pivot International states “This acquisition further expands our European scale of operations and positions Pivot for substantial European growth as a result.”

The acquisition is Pivot’s fifth in the last 24 months continuing its substantial growth trajectory since 2012.

Mark Dohnalek, Pivot International President and Chief Executive Officer describes the company’s growth strategy as “an aggressive calibrated approach to organic and acquired competencies, expertise and assets to help customers meet market needs and global clients needs most effectively. “

Grant King BlueWide Co-Founder and Design and Development Director says “the integration of Pivot International capabilities with WideBlue’s multi-disciplinary technical team and of product, mechanical, electronic and software engineers, physicists and optical designers will enhance its capabilities to deliver innovative solutions from concept through commercialization of products in the consumer, commercial, medical and scientific industries while working with a range of clients from inventors to multinational organizations and collaborating with Universities and Research Organizations across the UK.”

WideBlue has designed a broad range of Class 1 and Class 2 medical devices that have achieved MHR and FDA certifications. The company holds many patents as a result of their innovation, expertise and knowledge. The company won many awards, including “Best Medical Design” in 2017 and “Best Product Design” in 2016. The firm won the 2017 European Product Design award in the “Designs for Society” and the Design for Life Science” categories.

Pivot’s compounded annual revenue growth in excess of 100% over the last 5 years demonstrates the company’s agility across a broad range of industries and product categories. This is the fifth acquisition for Pivot since the beginning of 2016. In January 2016, the company purchased Mid-Continent Custom Electronics (MCCE) followed by the acquisition of DigitTron in March 2016, Avatar Engineering in May 2017 and Electronic Design and Manufacturing (EDM) in September 2017.

Pivot International also continues to build its portfolio of brands, talent and resources adding staff in London, UK to support the European market, an office in Hong Kong to support the Asian market, expanding its US national sales force, as well as building company-owned manufacturing plants in the US and Asia. Pivot’s company-owned global resources provide a unique ability to engage the world’s top talent to develop and engineer product and the world’s most efficient and effective manufacturer for any product format.

Pivot has a 45-year track record of outstanding performance, innovation, quality and design, engineering and manufacturing as a single-source expert serving clients in a broad range of industries including biometric/security products, wearable technology, touchscreen technology, medical, wireless, fitness, electronic components, agriculture, building operations and consumer products.

Mark Dohnalek, President & CEO affirms, “I am committed to ensuring that Pivot has the global capabilities to manufacture in the US, UK and Asia so that we can deliver the most efficient solution for our clients all over the world.”